The OASYS Healthcare management team has over 50 years of providing OEM medical solutions to our valued partners globally.

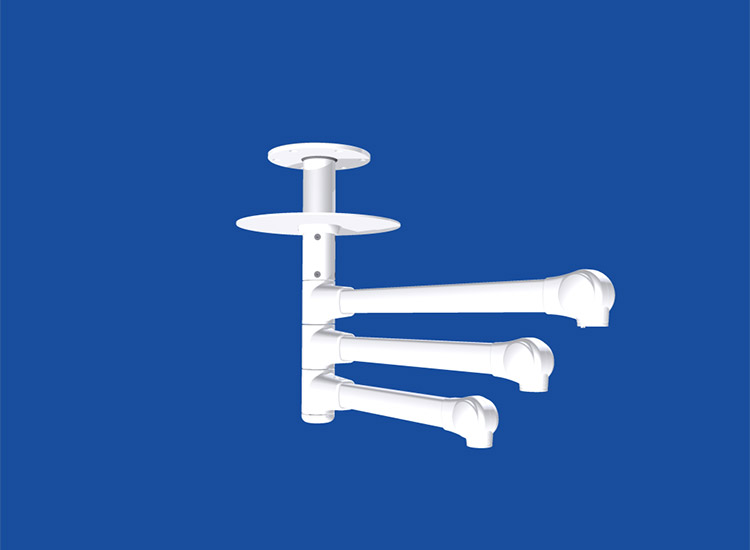

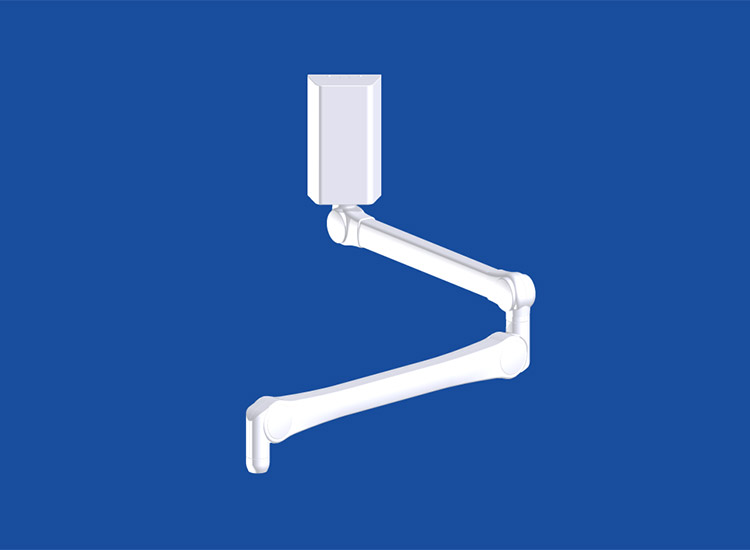

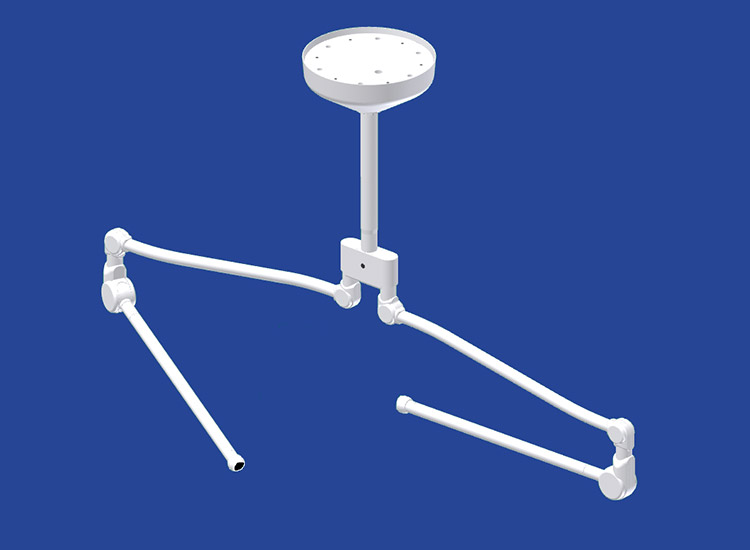

OASYS is a customer-oriented company with the shortest lead times in our field. We pride ourselves on providing the most innovative medical spring arms, mounting, support and mobility solutions in the industry.

Our products support Examination Lights, Operating Room Lights, Medical Monitors, Cameras and much more. OASYS products are crucial to doctors and surgeons that rely on our quality products to provide the best possible patient outcomes.

OASYS Healthcare is committed to using environmentally sustainable materials and processes throughout the production cycle.

We as a company reduce, reuse and recycle in a safe friendly manner. OASYS packaging consist of 90% recycled materials and we are constantly looking for ways to reduce our ecological footprint.

COMMITTED TO QUALITY.

COMMITTED TO YOU.

Quality comes first

Quality is the number one priority at OASYS Healthcare; as our President says, “We have to be able to sleep at night, we cannot let our customer be the first line of defence."

Quality tested at more than 5 times the cycles of our competitors

Throughout the design process, our products go through rigorous stress and cycle testing. We test at a minimum of 5 x times the cycles of any of our nearest competitors.

Longest lasting spring arms in the industry

Our products are the highest quality and longest lasting in the industry; making your decision to partner with OASYS a long term and sound investment.