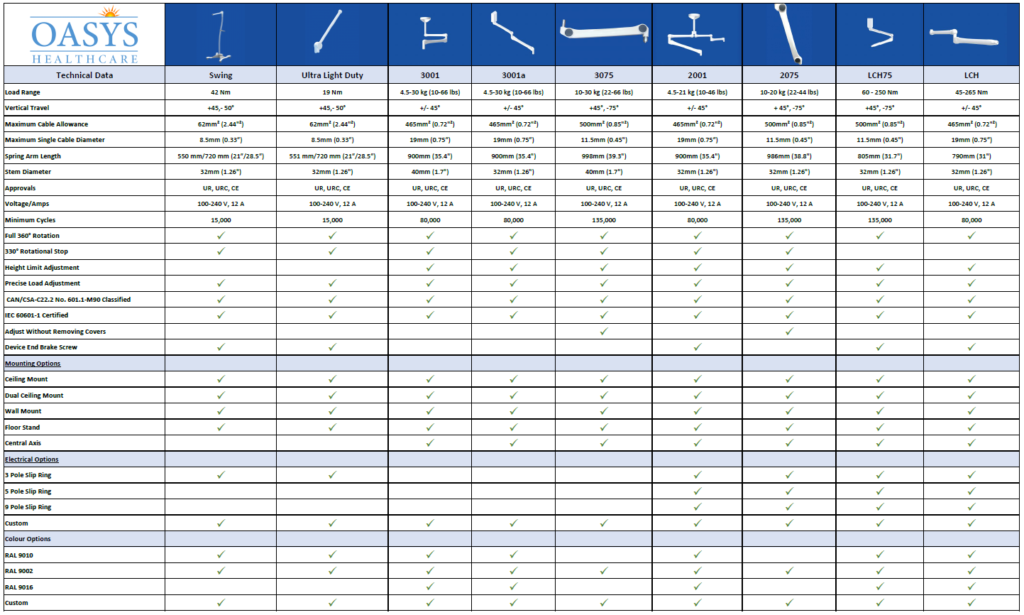

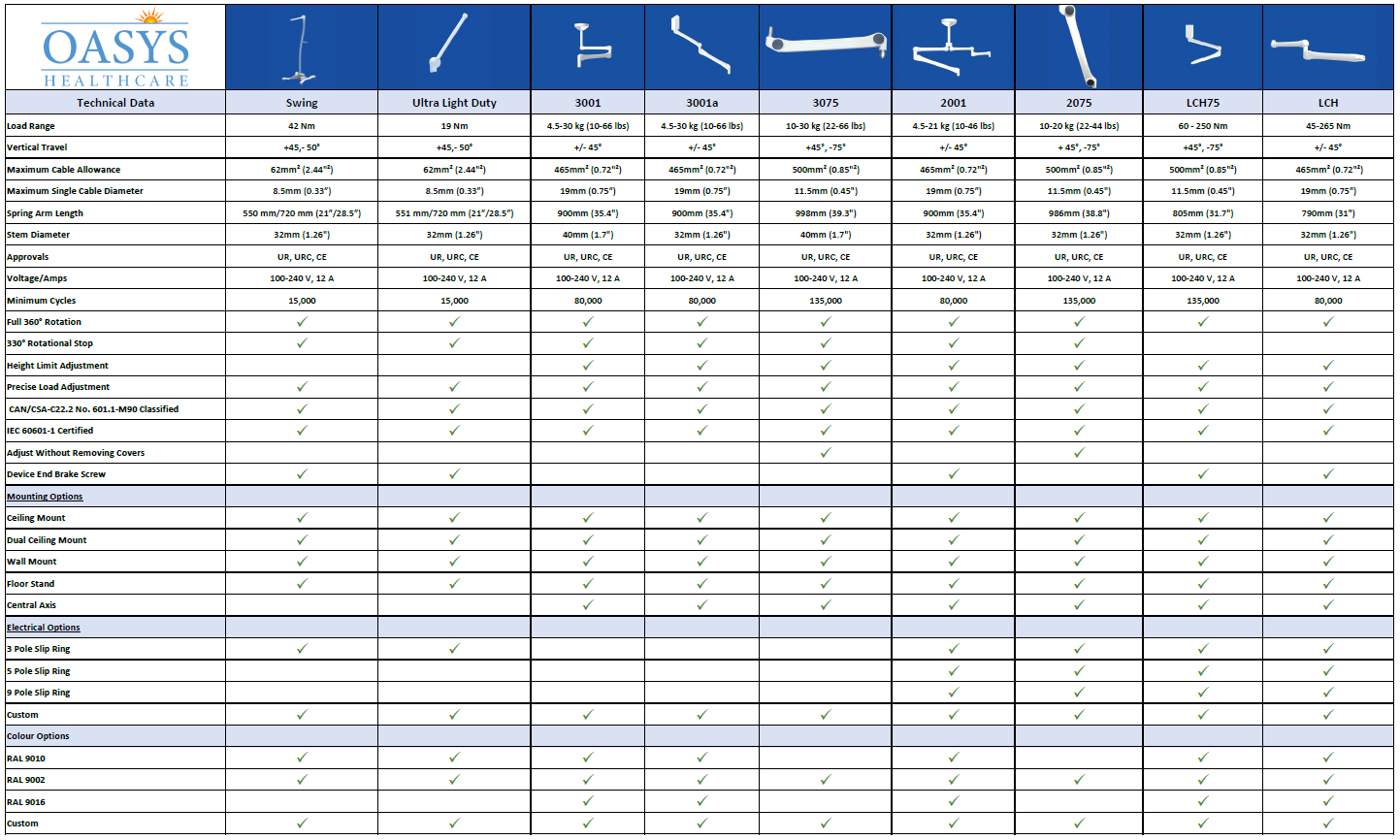

The datasheet provided showcases the technical specifications and options available for all OASYS Healthcare Spring Arms. These systems are designed for applications requiring flexible support and precise positioning of various devices. Below is a closer look at what each section of the table is conveying.

Overview of Suspension Arm Systems

Spring arms are critical components in medical, industrial, and professional environments where devices such as monitors, lights, and instruments need to be precisely positioned and supported. This table details several models, highlighting their technical specifications, certifications, and mounting options, making it easier for professionals to choose the right system for their needs.

Technical Specifications

1. Load Range:

This column indicates the weight capacity each model can support. The range spans from the lightweight Ultra Light Duty (19 Nm) to the heavy-duty LCH models (up to 265 Nm), accommodating different application needs from small instruments to larger, heavier equipment.

The Medium duty product lines like the 3075 and 3001 spring arms can support loads up to 30kg (66 lbs).

2. Vertical Travel:

Describes the angular movement range, crucial for applications needing significant vertical adjustment. Models vary, with some allowing movement from +45° to -75°, providing extensive flexibility.

3. Maximum Cable Allowance and Diameter:

Refers to the cross-sectional area and diameter of the cables these arms can accommodate. This is vital for routing power and data cables through the arms without obstruction. The maximum ranges from 62 mm² in lighter models to 500 mm² in more robust systems.

4. Spring Arm Length and Stem Diameter:

Specifies the length of the spring arm and the diameter of the supporting stem, impacting the reach and stability of the arm. The spring arm length ranges from 550 mm to nearly a meter, while the stem diameters are either 32 mm or 40 mm, ensuring compatibility with various installations.

Certifications and Standards

1. Approvals:

All models are certified under standards such as UR, URC, and CE, ensuring compliance with international safety and performance regulations. This is essential for medical and industrial applications where regulatory adherence is mandatory.

2. IEC and CAN/CSA Certifications:

Indicates compliance with specific international and Canadian standards, enhancing reliability and safety for sensitive environments like medical facilities.

Functional Features

1. Rotation and Adjustment:

Most models offer full 360° rotation, with some also including a 330° rotational stop. Height limit and load adjustments are available in several models, providing precise control over the positioning.

2. Mounting Options:

Flexibility in mounting is crucial for installation in diverse environments. Options include ceiling, dual ceiling, wall, floor stands, and central axis mounts, accommodating various setup requirements.

3. Electrical Options:

Slip ring configurations (3, 5, and 9 pole) allow for the transmission of electrical signals or power, catering to specific electrical needs of the mounted devices.

Customization and Colors

1. Color Options:

Standard colors (RAL 9010, 9002, and 9016) and custom color options are available, allowing the arms to blend seamlessly with different aesthetic and functional settings.

2. Custom Features:

For unique applications, custom configurations are offered, ensuring the suspension arm systems meet specific operational demands.

Conclusion

The table serves as a comprehensive guide for selecting suspension arm systems based on technical requirements, regulatory compliance, and installation preferences. It provides critical information to help professionals make informed decisions for integrating these systems into their setups, ensuring that they get the precise control and flexibility needed for their specific applications. Whether for medical, industrial, or professional environments, understanding these specifications ensures optimal performance and reliability of the suspension systems in use.